Vacuum Heat Treatment Furnace

Vacuum Sintering Furnace

Vacuum Brazing Furnace

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)

Please send us your inquiry about the customization of other furnace types or related questions about vacuum furnace. We will reply you immediately. Thank you.

Downloads

Downloads

All documents in the overview

News & Press

News & Press

All news at a glance

Request

Request

Send us a message

Email: contact@vacfurnace.com

Tel : +86-21-50878190

Wechat : 2210154395

Address: NO.1299, XinJinQiao Road, Pudong New Area, Shanghai, China.

Copyright © 2010-2021 Shanghai Gehang Vacuum Technology Co.,Ltd. All Rights Reserved.

ITO target applications and solutions

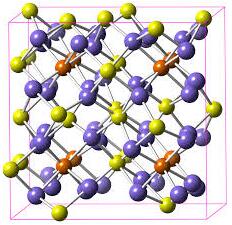

Indium tin oxide (ITO) crystal structure

Indium tin oxide (ITO) is an n-type semiconductor formed by doping In2O3 with tin. The crystal structure is In2O3. The In2O3 structure has two forms, one is the cubic ferromanganese structure and the other is the hexagonal corundum structure. The cubic ferromanganese structure is the most common In2O3 structure, as shown in Figure 1. When tin oxide is doped into indium oxide to form an indium tin oxide solid solution, a highly degenerate n-type semiconductor is produced, in which a certain number of In3+ positions are replaced by Sn4+, resulting in a large number of point defects in the ITO lattice At the same time, a large number of free electrons are generated. Point defects and free electrons can act as carriers under the electric field, so it shows excellent conductivity.

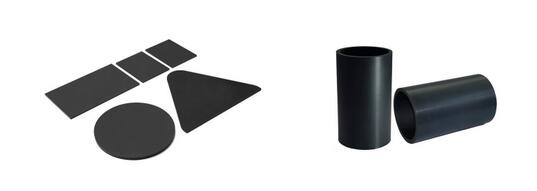

ITO target characteristics

ITO target material is a special functional ceramic material of indium tin oxide. It is a high-tech product of deep processing of metal indium and is mainly used to produce ITO film. As an n-type semiconductor ceramic film, ITO film has good electrical conductivity; high hardness, wear resistance, and good chemical etching; high visible light transmittance; more than 85% ultraviolet absorption rate, higher than 80% infrared reflectance; And has the characteristics of microwave attenuation rate greater than 85%.

ITO thin film process

The application of ITO in various fields revolves around its excellent properties of transparency and conductivity. The optical properties of ITO films are mainly affected by two factors: the optical band gap and the plasma oscillation frequency. The former determines the spectral absorption range, and the latter determines the spectral reflection range and intensity. In general, ITO has higher absorptivity in the short-wavelength region, higher reflectivity in the long-wavelength range, and highest transmittance in the visible light range. Taking 100nm ITO as an example, the average transmittance in the 400-900nm wavelength range is as high as 92.8%.

The performance of ITO film is mainly determined by the preparation process, and heat treatment is often used as a means of auxiliary optimization. In order to obtain an ITO film with good conductivity, high transmittance, and flat surface morphology, it is necessary to select appropriate deposition methods and optimize process parameters. Common coating methods include electron beam evaporation and magnetron sputtering.

The main principle of electron beam evaporation: In a high vacuum environment, the high-energy electrons emitted by the electron gun will bombard the surface of the ITO target material under the action of the electric field and magnetic field to convert the kinetic energy into heat energy, and the target material will heat up and become a molten state or evaporate directly. , ITO film is deposited on the surface of the substrate.

Magnetron sputtering belongs to the category of glow discharge and uses the principle of cathode sputtering for coating. The film particles originate from the cathode sputtering effect of argon ions on the cathode ITO target material in the glow discharge. After the argon ions sputter down the target atoms, they are deposited on the surface of the substrate to form the required ITO film.

ITO application

The ITO downstream industry is mainly the conductive glass technology in the flat panel display industry, that is, on the basis of soda-lime-based or silicon-boron-based substrate glass, coated with a layer of indium tin oxide film. In the flat panel display industry, it is used in touch screens and liquid crystal panels. The touch screen field uses TP-ITO conductive glass, while the liquid crystal panel field uses LCD-ITO conductive glass. The main difference between the two is that LCD-ITO conductive glass is also coated with a layer of silicon dioxide before the ITO layer is plated. The barrier layer prevents the sodium ions on the substrate glass from diffusing into the liquid crystal in the cell.

LCD Monitor:

Liquid crystal displays mainly use ITO conductive glass.

The reason why liquid crystal displays can display specific patterns is mainly that the transparent electrodes on the conductive glass are etched into electrodes of specific shapes. After appropriate voltage signals are applied to these electrodes, the liquid crystal molecules with dipole moments are specified under the action of an electric field. Arrangement of the aspect, and then show the pattern corresponding to the electrode wavelength. At present, ITO has the best light transmittance and conductivity of transparent electrodes of liquid crystal displays, and it is easy to etch fine patterns in acid.

touch screen:

Whether it is a resistive touch screen or a capacitive touch screen, the working surface is based on ITO coating.

The resistive touch screen, when the surface is touched, bends downwards, and allows the two layers of ITO coating spaced below to contact each other and connect the circuit at this point, the resistance changes, and signals are generated in both X and Y directions, and then Send touch screen controller.

The surface capacitive touch screen only uses a single layer of ITO, when a finger touches the surface of the screen, a certain amount of electric charge will be transferred to the human body. In order to recover these charge losses, charges are replenished from the four corners of the screen, and the amount of charge replenished in each direction is proportional to the distance of the touch point, and the position of the touch point is calculated.

The projected capacitive touch screen led by IPHONE uses multi-layer ITO layers to form a matrix distribution. The X-axis and Y-axis cross-distribution are used as the capacitive matrix. When a finger touches the screen, the X and Y axes can be scanned to detect the touch The change in capacitance at the touch position can be used to calculate where the finger is. Based on this architecture, the projected capacitor can achieve multi-touch operation.

In addition, IIO film has been widely used in many fields such as curtain wall glass, solar cells, aerospace aircraft, automobile anti-fog glass, microwave shielding and protective glasses, sensors.

ITO development status

For a long time, the core technology of ITO target materials has been controlled by Mitsui, Tosoh, Hitachi, Sumitomo, JX, Samsung Corning, Umicore and other large companies, and their atmospheric sintering technology has been relatively mature.

my country is the world’s largest demand country for ITO targets, accounting for 25% of the world’s demand. As an important raw material for display panels, although ITO targets have entered the Red Sea market, the localization rate is not high. Before 2019, about 90% of ITO targets need to be imported.

Although there are more than 20 target companies in China, the progress is not smooth, and mass supply is generally not available. Until 2017, the domestically produced ITO target products and technical level have greatly improved, gradually catching up with the international leading level. Domestic representative companies include Pioneer Group, Yingri Technology, Jinglian Optoelectronics, and Oulai Targets.

As OLED replaces LCD to become the mainstream of display technology, the market demand for ITO target materials may no longer grow at a high speed, turning to a steady development trend.

On the other hand, the price war in the ITO target market has been going on for a long time. Although there is a trend of rising prices in the market at this stage, there are not a few domestic companies deploying ITO target business, and market competition pressure will become increasingly fierce.