Vacuum Heat Treatment Furnace

Vacuum Sintering Furnace

Vacuum Brazing Furnace

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)

Please send us your inquiry about the customization of other furnace types or related questions about vacuum furnace. We will reply you immediately. Thank you.

Downloads

Downloads

All documents in the overview

News & Press

News & Press

All news at a glance

Request

Request

Send us a message

Email: contact@vacfurnace.com

Tel : +86-21-50878190

Wechat : 2210154395

Address: NO.1299, XinJinQiao Road, Pudong New Area, Shanghai, China.

Copyright © 2010-2021 Shanghai Gehang Vacuum Technology Co.,Ltd. All Rights Reserved.

Application of DPF filter

Working principle of diesel particulate filter (DPF carrier)

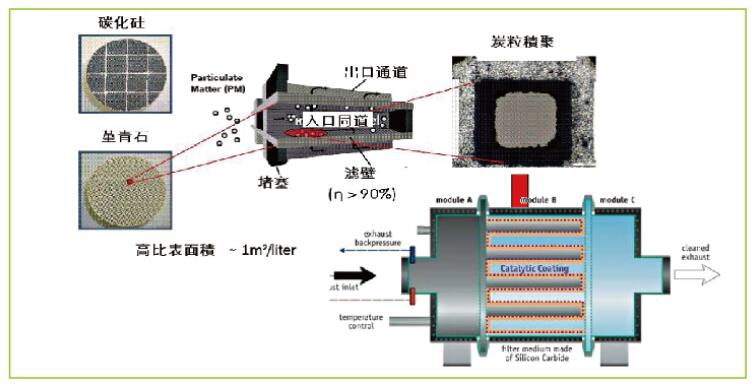

Diesel Particulate Filter (DPF. Diesel Particulate Filter) is a wall-flow honeycomb ceramic with cordierite or silicon carbide as raw material. The main component contained in the exhaust gas of diesel engine is carbon particles, and the particle trap is It is installed in the exhaust system of diesel vehicles and reduces the particulate matter (PM) in the exhaust by filtration. The filtering efficiency of carbon particles can reach more than 95%. The soluble organic component SOF (mainly high boiling point HC) can also be partially Catch. Working principle of particle trap:

By alternately blocking both ends of the pores of the honeycomb porous ceramics, PM is filtered and removed by using the ceramic wall pores.

DPF particulate trap catalyst

DPF has the following characteristics:

1: The coefficient of thermal expansion is relatively small, high temperature resistance, good thermal shock resistance

2: Large filtration specific surface area, uniform distribution of micropores and high hole attack rate

3: Small back pressure

4: Good product durability

5: The filtering effect of soot particles is high, generally more than 90%, and it is suitable for a variety of regeneration methods

Best exhaust gas purifier (active regeneration + remote monitoring)

Composition of BST diesel exhaust purifier

It is composed of oxidation catalyst (DOC), particle trap (DPF), fuel injection system (high temperature cleaning device), electronic monitoring and control unit). Diesel exhaust purifier that can achieve active regeneration without additives. The remote monitoring function can be realized, and the mobile terminal and the PC terminal can monitor at the same time.

DPF Filter Substrate

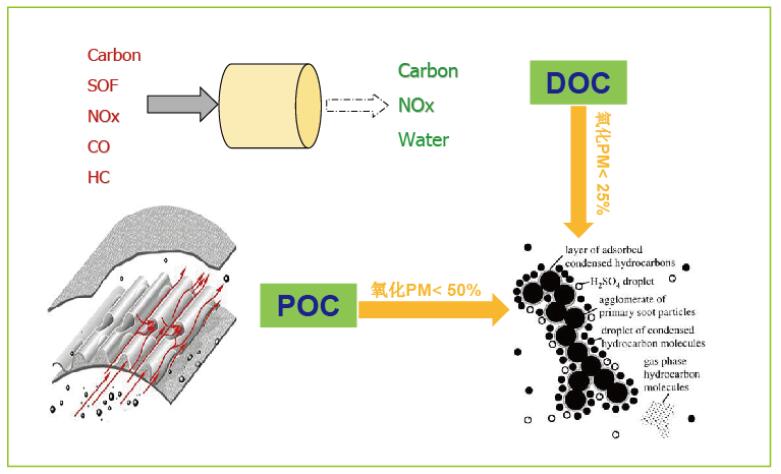

DOC oxidation catalytic converter

Working Process

The carbon monoxide (CO) and hydrocarbon (HC) emitted from the diesel engine are reduced by an oxidizing catalyst (DOC), and then the ultrafine nano-carbon soot particles (PM ) It is trapped in the DPF to achieve the purpose of reducing pollutant gas and soot particulate emissions. The electronic control unit monitors the pressure value in the system in real time. When the pressure value in the system reaches the regeneration setting value, the electronic control unit automatically controls the high temperature cleaning device to increase the temperature in the system and fully reduce the particulate matter trapped in the DPF To achieve the purpose of automatically cleaning the particle trap. The system can be reused for a long time.

Installed in the exhaust system of diesel engine, through catalytic oxidation reaction, it can reduce the exhaust gas post-treatment of carbon monoxide (CO), hydrocarbon (THC) and part of soluble matter (SOF) in particulate matter (PM) Device, the overall conversion efficiency of CO, THC, SOF is more than 90%. It is often used together with POC, DPF, and SCR in the national IV aftertreatment program. In some light diesel vehicles with better internal purification technology and its own EGR system Can also be used alone.

DOC / POC oxidation catalyst

Ministry of Environmental Protection: DOC + DPF is the final solution for diesel particulate matter, and should increase the matching and promotion of new vehicles and in-use vehicles.

Related products: silicon carbide sintering furnace, vacuum degreasing furnace, dewaxing furnace

Edited by: Kevin Liu;

Copyright: SIMUWU Vacuum Furnace