Vacuum Heat Treatment Furnace

Vacuum Sintering Furnace

Vacuum Brazing Furnace

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)

Please send us your inquiry about the customization of other furnace types or related questions about vacuum furnace. We will reply you immediately. Thank you.

Downloads

Downloads

All documents in the overview

News & Press

News & Press

All news at a glance

Request

Request

Send us a message

Email: contact@vacfurnace.com

Tel : +86-21-50878190

Wechat : 2210154395

Address: NO.1299, XinJinQiao Road, Pudong New Area, Shanghai, China.

Copyright © 2010-2021 Shanghai Gehang Vacuum Technology Co.,Ltd. All Rights Reserved.

Vacuum heat treatment of aluminum alloy die castings

The lightweight and green manufacturing of automobiles has created a demand for high-stability, high-strength aluminum alloy materials. Aiming at the problems of insufficient strength and stability of the existing aluminum alloy body components, the vacuum heat treatment process was optimized by taking the aluminum alloy casting of the lower tray of the automobile as an example, and a better vacuum heat treatment process route was obtained. The results show that the mechanical properties of the lower tray castings are significantly improved after the vacuum heat treatment method is strengthened, and the strength of the castings is further strengthened.

Due to the low density of aluminum alloy, it can well meet the material requirements for lightweight body materials. Its strength is high, approaching or exceeding high-quality steel, and it has good plasticity, easy processing and molding, and has excellent electrical conductivity, thermal conductivity and corrosion resistance. It has been widely used in the field of automobile manufacturing, and is the second most used alloy in the automobile field after steel.

At present, the manufacturing methods of aluminum alloy components mainly include forging and casting. Cast aluminum alloy has advantages over forged aluminum alloy due to its raw materials and processing costs, and cast aluminum alloy can be strengthened after vacuum heat treatment process, which can meet the use of aluminum alloy components in automobiles. Therefore, cast aluminum alloys are widely used in the automotive field.

1 Purpose of vacuum heat treatment of aluminum alloy

(1) It can strengthen the alloy, improve the metallographic structure of aluminum alloy, improve the mechanical properties of aluminum alloy castings, improve the cutting performance and welding performance of aluminum alloy;

(2) It can eliminate the internal stress caused by the uneven cooling rate when the casting is crystallized and solidified due to uneven wall thickness of the casting, excessive wall thickness at the transfer point, etc., and stabilize the structure of the aluminum alloy casting and the outline size of the part;

(3) Prevent and eliminate volume changes caused by high-temperature phase transformation, eliminate intergranular and component segregation, and homogenize the structure.

2 Problems in aluminum alloy castings

High-vacuum die-casting aluminum alloy lower tray component sample, before vacuum heat treatment, the mechanical properties of the casting are that the tensile strength is less than 230 MPa, the yield strength is less than 180 MPa, and the elongation is less than 5%; in the load airtight test, the gas leakage rate It reaches 0.35 kPa/min, which is seriously inconsistent with the use requirements, indicating that the casting has large deformation due to insufficient strength; the thread strength of the threaded hole of the casting is insufficient, and cannot provide the locking force required by the product. During the assembly process, the thread teeth are prone to breakage , and easy to loosen. In order to improve the service strength and dimensional stability of the above-mentioned aluminum alloy castings, it is necessary to optimize the vacuum heat treatment process to achieve the purpose of strengthening the castings.

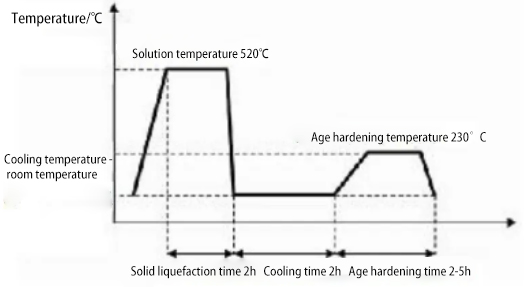

After many repeated tests and verifications, the vacuum heat treatment process of the aluminum alloy on the lower tray is determined as follows: put the aluminum alloy castings on the lower tray into a solution resistance furnace for solid solution, the solution temperature is 520°C, and the solution time is 2 h, so that the alloy inside The soluble phase is fully dissolved. Then the casting is cooled to room temperature for 2 hours by air cooling, so that the casting is quenched. The purpose is to make the strengthened components dissolve in the alloy to the maximum extent, and strengthen the aluminum alloy casting. Finally, artificial overaging is carried out, and the casting is reheated to 230°C and kept for 2-5 hours, so that the strength is slightly reduced and the plasticity is improved, so that the aluminum alloy casting can obtain better mechanical properties.

The temperature change curve of the lower tray aluminum alloy casting vacuum heat treatment process is shown in the figure below.

In this paper, in view of the problems of insufficient strength, residual internal stress and unstable structure and size of die-casting aluminum alloy components for automobiles, the aluminum alloy castings of the lower tray of automobiles are taken as an example, and the vacuum heat treatment is optimized, and the mechanical properties of the castings are tested, The torque test and air tightness test analysis are used to evaluate the performance of the castings after vacuum heat treatment. The results show that after the vacuum heat treatment process, the mechanical properties of the castings have been significantly improved compared with those before vacuum heat treatment, and the strength of the castings has been greatly improved, the structure of the casting after vacuum heat treatment is stable, the internal stress is small, and the structure and size are stable. It shows that the best vacuum heat treatment process for the lower tray aluminum alloy casting is solid solution at 520 ℃ and heat preservation for 2 hours, then air cooling for 2 hours and then cooling to room temperature , artificial overaging at 230°C, heat preservation for 2 – 5 h.

Vacuum furnace equipment selection: The vacuum heat treatment furnace produced by SIMUWU is a high-quality product for vacuum heat treatment process. Good temperature control accuracy and temperature control uniformity ensure the effective vacuum heat treatment process. The equipment is easy to manage and maintain, greatly reducing maintenance costs. SIMUWU company focuses on the manufacture of vacuum furnaces, has more than ten years of relevant experience, and has a good reputation in the field of vacuum furnace manufacturing. The product line includes vacuum air quenching furnace, vacuum oil quenching furnace, vacuum brazing furnace, etc., which are widely sold in developed and developing countries.

Learn More:

Selection Guide for Vacuum Sintering Furnaces

MIM degreasing and sintering for ceramic hard alloy

Vacuum Oil Quenching for steel hardening heat treatment