Vacuum Heat Treatment Furnace

Vacuum Sintering Furnace

Vacuum Brazing Furnace

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)

Please send us your inquiry about the customization of other furnace types or related questions about vacuum furnace. We will reply you immediately. Thank you.

Downloads

Downloads

All documents in the overview

News & Press

News & Press

All news at a glance

Request

Request

Send us a message

Email: contact@vacfurnace.com

Tel : +86-21-50878190

Wechat : 2210154395

Address: NO.1299, XinJinQiao Road, Pudong New Area, Shanghai, China.

Copyright © 2010-2021 Shanghai Gehang Vacuum Technology Co.,Ltd. All Rights Reserved.

Heat Treatment of Buick Automatic Transmission Parts on Low Pressure Vacuum Carburizing Furnace

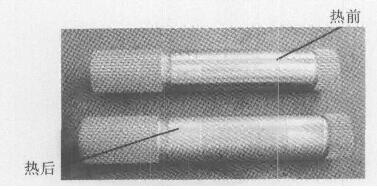

Due to the material selection and shape design of some parts of Buick sedan 4T65E transmission, the heat treatment deformation is difficult to control, and the most typical ones are thin-walled parts such as the final deceleration sun gear shaft. The part is made of SAE 4130 annealed welded seamless steel pipe, the wall thickness of the bearing rail is only 2mm, and the bearing rail is ground and polished after heating, and the machining allowance on one side is only 0.02mm. After the conventional controllable atmosphere carburizing and quenching process, the deformation of the parts is difficult to control, and the outer diameter of the bearing gear is seriously deformed by more than 0.10mm, resulting in the bearing gear not being ground and the M value of the external splines at both ends after heating. The amount of fluctuation is also large, which affects the assembly, and the qualified rate of finished products is only about 70%.

Vacuum carburizing is a high-speed carburizing process that pulses into carburizing atmosphere (pure propane gas) and protective atmosphere (pure nitrogen gas) at high temperature. In this process, the oxygen content in the furnace is extremely low, and the carbon potential, the main control parameter in the conventional process, cannot be measured. For the vacuum carburizing process, the most important process parameters are carburizing temperature, vacuum degree, beat per pulse and gas flow.

According to the technical requirements of heat treatment of parts, Shanghai Automobile Co., Ltd. Automobile Gear Factory uses the patented technology of French ECM Industrial Furnace Company – low-pressure carburizing process simulation software to carry out computer simulation analysis, and generates the entire heat treatment process program, and then input it to the user for production Executed on the computer on site.

Design special charging fixture for vacuum furnace

Because the cooling medium of gas quenching and oil quenching is different, there are big differences in the cooling method, the contact method between the medium and the workpiece, the circulation of the medium and the cooling method, so the design of the part loading fixture when using the gas quenching process is a very important part. According to the characteristics of gas quenching, Shanghai Automobile Co., Ltd. Automobile Gear Factory has designed special materials for the main reduction sun gear shaft parts. High-purity nitrogen was used for quenching, and the gas quenching pressure was 1.6 MPa.

Effect

After adopting the new low-pressure vacuum carburizing process, the post-heat pass rate of the main deceleration sun gear shaft increased from 70% to more than 99.5%, which exceeded the general quality level in the United States, and completely solved the quality problems that occurred during the assembly of this part before. .

Economic benefits

Due to the improvement of the qualified rate of parts, and the elimination of post-cleaning and cleaning shot peening during the heat treatment process, the manufacturing cost of the part is greatly reduced.

Other advantages

Low-pressure vacuum carburizing and high-pressure gas quenching technology are relatively advanced heat treatment new technologies in the world, and have many advantages compared with traditional atmosphere carburizing and oil quenching technology.

a. Vacuum carburizing speed is fast. The use of high temperature carburizing process can significantly shorten the process time (saving 20%~40%), and reduce the heat preservation time of parts at high temperature, which is conducive to reducing high temperature distortion.

b. The quenching intensity of high-pressure gas quenching is lower than that of oil quenching. Under the premise of ensuring the hardness of the parts, the cooling deformation of the parts is also much smaller.

c. There are no three stages in the oil quenching process in the high-pressure gas quenching process, only the convection conduction process, and the workpiece is easy to obtain higher hardness.

d. There is no oxygen atom in the process of low pressure vacuum carburizing, which can avoid the appearance of bad structure on the surface of the workpiece and improve the service performance of the workpiece.

e. The surface cleanliness of the treated workpiece is high, no post-cleaning and shot blasting procedures are required, and the production cost is reduced.

f. Environmental protection is good. No fire curtain, no SO2, CO emission problem.

Summarize:

For parts with strict deformation requirements, users can consider conducting new process test research on a low-pressure vacuum carburizing furnace. When choosing suitable tooling and new low pressure vacuum carburizing process, the technical problems of these parts can be solved on the low pressure vacuum carburizing furnace. Since the deformation of the parts is relatively small, the machining process of the parts can be shortened as a whole, and the amount of grinding after heat can be reduced, so the production cost of the parts can be greatly reduced.

Equipment selection: The RVN series vacuum nitriding furnace produced by SIMUWU is a high-quality product for the vacuum heat treatment of tooling and molds. The good temperature control accuracy and temperature control uniformity ensure the effective progress of the vacuum nitriding process. SIMUWU specializes in the manufacture of vacuum furnaces, has more than ten years of relevant experience, and has a good reputation in the field of vacuum furnace manufacturing. The product line includes vacuum air quenching furnace, vacuum oil quenching furnace, vacuum brazing furnace, etc., which are widely sold in developed and developing countries.