Vacuum Heat Treatment Furnace

Vacuum Sintering Furnace

Vacuum Brazing Furnace

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)

Please send us your inquiry about the customization of other furnace types or related questions about vacuum furnace. We will reply you immediately. Thank you.

Downloads

Downloads

All documents in the overview

News & Press

News & Press

All news at a glance

Request

Request

Send us a message

Email: contact@vacfurnace.com

Tel : +86-21-50878190

Wechat : 2210154395

Address: NO.1299, XinJinQiao Road, Pudong New Area, Shanghai, China.

Copyright © 2010-2021 Shanghai Gehang Vacuum Technology Co.,Ltd. All Rights Reserved.

Sintering furnace technology in the e-cigarette industry

Electronic cigarette (Electronic cigarette or E-cigarette), also known as Electronic cigarette, Electronic cigarette, virtual cigarette, Electronic cigarette atomizer, is mainly used to replace cigarettes and assist smoking cessation.E-cigarettes have become a significant trend in the tobacco market.

Looking into the future, the sintering technology involved in the e-cigarette industry has become one of the leading innovative technologies in the new industry. Sintering technology refers to the processing program and sintering process system selected according to the characteristics of raw materials.It has a direct and important influence on the output and quality of sintering production.According to the internal law of sintering process, this technology selects the appropriate process flow and operation system, USES the modern scientific and technological achievements, strengthens the sintering production process, can obtain the advanced technical and economic index, guarantees the realization of high yield, high quality, low consumption.The production process has.Raw material mixing, feeding, injection molding, degreasing, vacuum sintering, conformation, polishing, PVD and other steps.

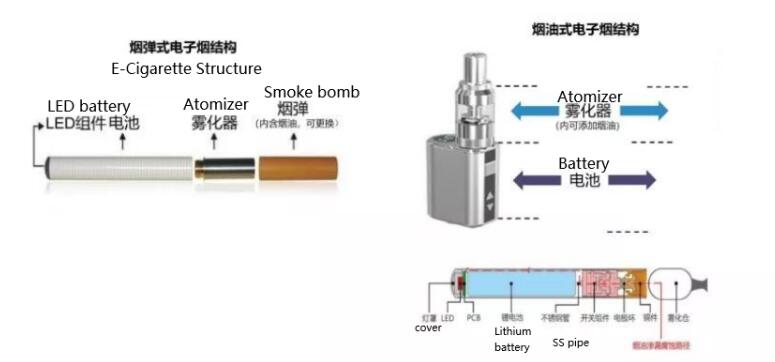

E-cigarette structure as below:

E-cigarette atomizers and their metal components, because the product is small, require high precision accessories.So MIM metal injection molding technology has played a major role in the e-cigarette industry.

Compared with casting, machining and pressing, MIM metal injection molding process is more efficient and precise.Because the metal powder injection molding products are very precise complex structural parts, size error, thin wall, hole thickness can achieve high accuracy.The advantages of the MIM process include complex shape, small size, and high output.

In the application of MIM process to realize the complex structure of accessories, the product surface can also be processed with various post-processing techniques, such as mirror polishing and PVD surface treatment, to achieve a variety of colors, types and effects can be customized according to customer requirements, flexible.

The most important parts of the MIM production line are feeding, injection machines, and the selection of degreasing and vacuum sintering furnaces.

SIMUWU catalytic degreasing furnace USES nitric acid or oxalic acid to remove POM by the degreasing method of nitrogen atmosphere charging and washing, which is safe and reliable. Compared with solvent degreasing, it has the advantages of larger yield and smaller performance.

The following are the degreasing furnace specifications of different specifications:

In addition, the SIMUWU vacuum sintering furnace has nitrogen, argon and hydrogen gas in different atmospheres, which can be customized according to different processes.

The use temperature of MIM sintering generally does not exceed 1300℃, and the equipment with the highest temperature of 1400℃ can be designed.Or customize SIMUWU standard RVS-M series vacuum debinding and sintering furnace.

dimension

(mm)

(C)

pressure

(Pa)

rising rate

(pa/h)

uniformity

(C)

capacity

(kg)

Edited by: Lucky Hu;

Copyright: SIMUWU Vacuum Furnace

Related products:

MIM sintering Furnace

Catalytic debinding furnace

Vacuum debinding&sintering furnace